Ensuring safety of mealworm products

With the growing demand for insect-based ingredients, particularly in the petfood and animal feed sector, it is ever more important to showcase product reliability and quality.

Subjected to the requirements of the food and feed industry, Ÿnsect goes above and beyond to ensure compliance with relevant regulations and petfood market standards but also to push the boundaries of innovation regarding mealworm housing and breeding.

The agri-food sector is constantly evolving. Alternative foods and farming systems are gradually taking the lead. In particular, insect-based products have come forward as one of these new food sources, specifically in the pet food and animal feed sectors. According to the International Platform of Insects for Food and Feed (IPIFF)1, the 1 billion euros invested since its establishment is expected to triple by 20252. With significant growth ascertained in the last few years, the industry has been shaped with rigor and structure by the manufacturers, hand in hand with researchers and competent public authorities, to guarantee high-quality products and compliance with the regulations in play.

Ÿnsect, as the world leader in the mealworm farming and manufacturing sectors, not only abides by these requirements but ensures they are met with the highest standards available on the market. With three farms located in Europe (in France and in the Netherlands) equipped with high-end technology, the company is shaping the future of insect farming and processing.

The petfood insect industry is bound by rules and regulations

In Europe, the pet food industry – and more generally the food and feed industry – is highly regulated. Petfood operators have to comply with the European “Food and feed law” which guarantees the safety of food and feed chains and is amongst the most stringent in the world.

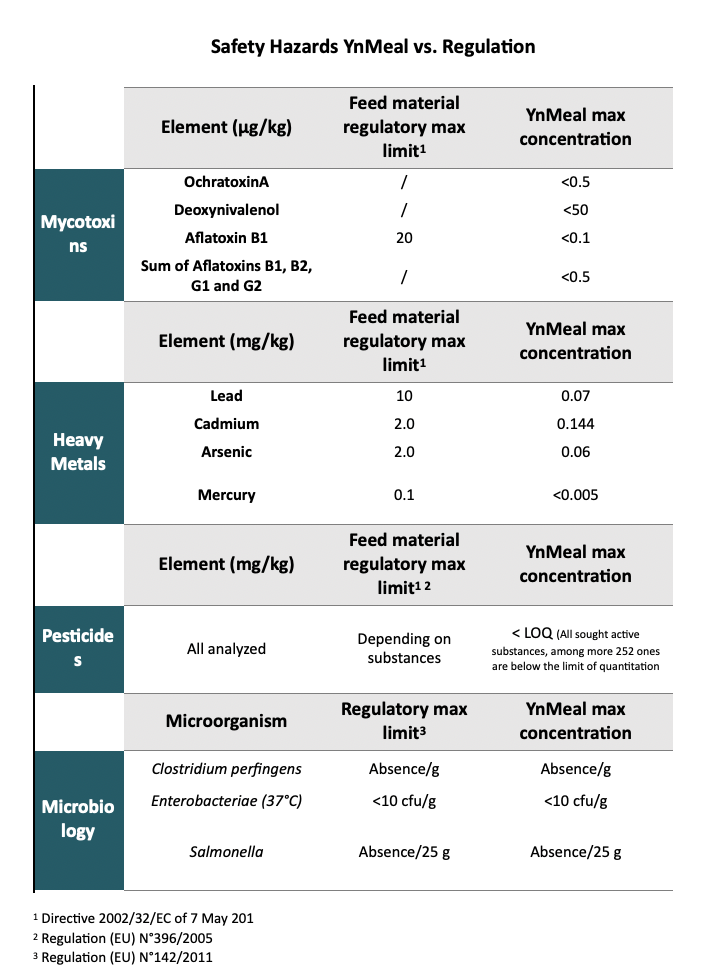

The mealworm industry makes no exception to the rule. Coercive requirements regarding risk analysis, traceability, good hygiene practices, etc. notably set criteria that guarantee the safety of the mealworm-based pet food products placed on the market. Compliance with these requirements is enforced by competent national authorities. As such, risks linked to the potential presence of contaminants such as pathogens (microbiological), heavy metals, pesticides and toxins are closely monitored and controlled.

Both as an insect farmer and manufacturer of mealworm-based products, Ÿnsect has implemented, applied, and integrated – according to the legislation – the required hygiene practices, traceability systems, and recall requisites throughout its farming systems and production lines. Whenever applicable, hazard analysis (microbiological, chemical, physical) is carried out in accordance with the European HACCP (Hazard Analysis and Critical Control Point) principles – or equivalent – to reduce or eliminate their occurrence. Control checkpoints, throughout the processing steps, are defined and implemented at each production site.

In the business of continuous improvement, Ÿnsect is committed to going above and beyond the simple application of these regulations, to deliver the highest product quality possible.

Going a mile further in terms of security

As strict as the regulations may be, nothing stops companies from implementing more extensive controls than what is required by law. With this in mind, Ÿnsect has gone a step further in its devotion to the safety of its products by validating various certifications such as ISO 9001 and FSSC 22000, among the most thorough, which have strict specifications and are recognized worldwide to further guarantee quality and safety within facilities.

Frequent supplementary checkpoints have been added to the mandatory protocol. For example, the monitoring of the compulsory processing method needed to validate processed animal protein product commercialisation, is repeated more frequently at Ÿnsect to further ensure the security of its insect-derived proteins. Innovative analysis technologies have also been specifically developed internally for the processing of mealworm-based products. Contaminant analysis methods have been adapted to insect – and specifically mealworm – matrices.

“At Ÿnsect, we fall under the same strict regime as any other operator of the animal pet food industry, but we also carry out controls that are specific to our industry, according to hazards and risks that are specific to the rearing of insects and production of insect-based end-products,” explains Noémie Beaudoin, Quality control expert at Ÿnsect.

Ÿnsect’s expertise optimizes product safety and quality

The insect farming facilities are under heavy scrutiny at Ÿnsect, with rigorous quality controls. Indeed, pursuant to European legislation, farmed insects fall under the farmed animals3 category, like any other animal. As such, they are subject to the majority of the standards that apply to livestock farming.

Everything that comes in and out of the factories goes through robust internal and external controls, including raw materials and finished products. In line with the analyses carried out on the end-product, Ÿnsect strictly monitors the rearing process, thus ensuring compliance with the agri-food legislation and guaranteeing the highest of standards.

Proactive on setting an example and breeding mealworms with the most relevant system possible, Ÿnsect has made innovative improvements to the breeding, monitoring and safety of insects. The safety and quality of the resulting insect-based product is therefore also enhanced.

An on-site team of entomologists, agri-food and quality experts, and an external veterinarian build in-house knowledge to guarantee insect health, biosecurity and end-product requirements. Workers receive accurate training and take part in ongoing workshops to ensure adhesion and compliance to biosecurity principles and understanding of health measures.

The next generation of mealworm farming

With safety in mind, the Ÿnsect facilities were built on this expertise to prevent insect and product contamination and to maximize security. Dry, compartmentalized, controlled, and stackable nurseries help maintain consistent, hygienic, disease-free, internal conditions so that production is largely unaffected by external factors. System consistency is notably increased through operational redundancy.

Additionally, extra attention is paid to the diet of the mealworms. Strict restrictions4 apply as to what the mealworms can be fed, to guarantee the safety of the whole feed and food chains and avoid the presence of undesirable substances. Regular analyses of the feeding substrate are notably performed to verify microbiological quality and the absence of contaminants. This expertise has helped tailor precisely to the mealworms’ needs, improving the quality, safety and consistency of the resulting end-products. Consumption risk is similar to other farmed animal fed with plant-based substrates, but the precise control over the mealworms’ diet ensures safe food and means that the final end-product is consistent in quality over time.

Ÿnsect draws on knowledge and innovation to offer the best products possible, constantly optimizing and improving equipment and solutions. In this spirit, a new mealworm farm is opening its doors in Amiens, France. This 4.0 farm will shine with state-of-the-art technologies and automation systems with the most avant-garde concepts on the market.

A huge amount of data (1 billion data points per day) will be generated, collected, analyzed and put to use to further guarantee all standards are respected. This monitoring system will not only ensure the mealworms are thriving and healthy but will optimize the management of the facility at an even more precise scale than it already is, to inform decision-making and ultimately develop an even more consistent product.

1. European equivalent to the North American Coalition for Insect Agriculture (NACIA)

2. https://ipiff.org/wp-content/uploads/2021/04/Apr-27-2021-IPIFF_The-European-market-of-insects-as-feed.pdf

3. “Any animal that is kept, fattened or bred by humans and used for the production of food, wool, fur, feathers, hides and skins or any other product obtained from animals or for other farming purpose.” Regulation (EC) No 1069/2009

4. https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=celex%3A32002L0032