Technology that improves pet food safety and quality

Vacuum coating plays a crucial role in preventing recontamination by pathogens such as Salmonella.

In pet food production, achieving the highest standards of product safety and quality is paramount. The focus on eradicating contamination risks, especially from pathogens like Salmonella, has led to innovative approaches in production processes.

Hygiene at every stage

A significant evolution in these processes is the shift to vacuum coating technologies in the final stages of production. Prior stages, such as extrusion and drying, use high pressure, temperature and time to eliminate Salmonella.

However, given the risk of recontamination, it is crucial to maintain hygiene in subsequent process steps, which often involve the addition of nutrients and liquids through vacuum coating technology.

80% more nutrient enrichment

Vacuum coating has revolutionized the way pet food is enriched. This technology allows healthy oils and fatty acids, such as omega 3 and 6, to penetrate each piece of kibble.

The kibble is mixed under a vacuum, and fats and other nutrients are sprayed on. When the vacuum is released, these additives go deep into the core of the kibble.

After this nutritious infusion, a slurry layer can be used to enhance aroma and taste, making the kibble irresistible to pets. To prevent potential stickiness from the slurry, a powder coating may be applied, yielding a final product that is both dry and strong.

Previously, enriching kibbles with oils and fatty acids was impractical due to absorption limits. With vacuum coating, up to 80% more of these vital nutrients can be integrated into every kibble.

Innovations in vacuum coating

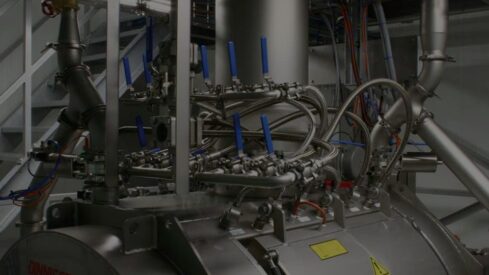

Preventing recontamination demands strict hygiene measures. Fortunately, recent years have brought about significant innovations in hygienic mixing and vacuum coating. The latest systems incorporate features specifically designed to prevent Salmonella growth, including body heating, hot and clean air injection systems, and clean-in-place (CIP) systems. These allow the equipment to be thoroughly sanitized without the need for disassembly. That maintains the highest standards of hygiene and safety in pet food production while minimizing downtime and operational disruptions.

Best of both worlds

Everyone wants the best for their pet. So each kibble must be perfectly safe and full of healthy nutrients, vitamins and minerals. Vacuum coating technology offers producers the best of both worlds: pet food full of essential fats and flavors without a greasy residue and – even more important – pet food that is safe from pathogens such as Salmonella.