Unlocking innovation: How drying technology brings new pet food concepts to life

From insect protein to upcycled seaweed – how the Harter Test Center solves the engineering challenges of next-generation pet food.

In the competitive pet food market, innovation is the primary driver of growth. Whether it is novel proteins, upcycled ingredients, or premium-quality snacks, manufacturers are constantly pushing boundaries. However, a great concept in the lab often hits a roadblock on the factory floor: the drying process.

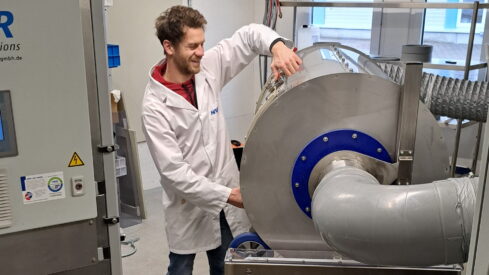

Standard off-the-shelf dryers often fail to meet the specific quality or energy requirements of these modern products. This is where the Harter Test Center in Southern Germany steps in. Managed by food technologist Fabian Baur, the center serves as an innovation hub where manufacturers test new recipes and “de-risk” their investment by proving feasibility before a full-scale system is built.

Using heat pump-based condensation drying, a technology refined over 30 years and 2,000+ installations, Harter helps companies transition from idea to industrial reality.

Here is how three different manufacturers used this technology to solve unique product challenges.

Case study #1: Insect larvae

A forward-thinking Italian company was developing a new product featuring Black Soldier Fly larvae.

The product requirements were strict. The larvae needed to be dried at a low temperature to reach exactly 96% dry matter content without clumping, preparing them for protein extraction and further processing.

“We conducted two series of tests at 55 ℃ and 75 C, respectively. These tests showed that 10 kg batches of larvae could not be dried in a chamber dryer,” reports Baur. Consequently, the Test Center Manager ran further tests, first in a continuous dryer and then in two different barrel dryers, varying the material and air routing.

Baur explains: “Ultimately, we achieved very good results in a closed barrel with horizontal air routing. The larvae did not clump together and were uniformly and thoroughly dry.”

The barrel rotates during drying. For the larvae tests, a slow rotation of 8 rpm was used, which is gentle on the product. Compared to chamber drying, mixing the larvae in a barrel makes it much easier to achieve exactly 96 percent dry matter content.

Case study #2: Seaweed

A Scandinavian company wanted to pioneer a sustainable “upcycling” solution. They processed seaweed for cosmetics and pharmaceuticals but wanted to turn the leftover waste, the leaves, into a mineral-rich pet food ingredient.

The engineering challenge was significant: seaweed leaves are slick and slimy, preventing air from passing through them. This meant drying in a single layer was the only option. Because the client required continuous processing, simple chamber dryers were ruled out.

After testing a belt dryer at 75C, the next challenge appeared: the leaves stuck to the stainless steel belt. The dryer was retrofitted with a plastic belt, which proved to be the ideal solution. Harter then designed a sophisticated five-belt system where the leaves dry in a single layer on the top three belts before falling to lower belts for finish drying.

This creative engineering allowed the customer to dry the material in just two hours while reducing the machinery’s physical footprint. By optimizing the process in the Test Center, throughput was increased by 40% before the final machine was even built.

Case study #3: Dog snacks

Innovation isn’t always about new ingredients; sometimes it is about modernizing the quality of a classic product. A dog snack manufacturer needed to replace an energy-intensive gas dryer that relied on ambient air and released exhaust air into the environment.

The challenge was replicating the exact texture and appearance of their existing product using a completely different, more sustainable technology.

To guarantee a result comparable to their home factory, the client brought their equipment to the Test Center to extrude refrigerated sausage meat onsite before the drying tests started.

Because the team expected the heat pump to match the quality of the original samples, all tests were performed in a chamber dryer. Testing revealed 40C as the “sweet spot” temperature. After drying for 14 to 48 hours (depending on the product), the snacks achieved the consistency, look, and feel desired by the customer.

The new chamber dryer uses a closed air circuit, meaning no fresh air is needed and no odors are released. The manufacturer achieved independence from the climate and seasons, significant energy savings (rated power: 27 kW), and a daily capacity of 3,210 kg, all while maintaining the premium quality their customers expect.

Conclusion

Innovation requires more than just a recipe. It requires a process that delivers consistent quality. Harter’s heat pump-based drying offers a closed-loop, exhaust-free system that is gentle on products and highly energy-efficient.

For executives looking to launch the next big pet food product, the path to success starts with feasibility. As Fabian Baur notes, the Test Center provides the reliable basis needed to design a system that fits perfectly into your process, whether you are drying snacks, insects, or something the market hasn’t even seen yet.